Jacking shaft

Jacking shaft – Microtunneling system

The jacking shaft, together with the pipeline, is the main element to be used in “trenchless” laying techniques. These have their main application in the following areas: sewage and drain pipeline laying; gas and water pipe installations, oil pipelines, guide pipes for telecommunications, cable ducts and underground canals. Among the special applications we find the installation of circular or rectangular sections for pedestrian or road underground passageways.

This technique can be used to overcome obstacles such as main roads, railway tracks, rivers, canals, buildings and airports which are on the route of the pipeline.

The pipes with a diameter lower than 900 mm and which do not allow men to go inside, are installed using remote control “microtunneling” systems. A length that varies between 80 m and 120 m can be reached. The “pipe jacking” system is used on the other hand mainly for bigger pipelines as an alternative to open cut trenches or other tunnel excavation systems. The lengths can be well over those of the microtunnel with intermediate jacking stations. The “pipe jacking” system can be used in any case for short crossings of canals, railway tracks, roads, etc. Various building methods are available which are suitable for cohesive and non-cohesive soils, both in dry conditions and with groundwater. There are also excavation techniques which are available for rocks, big-sized erratic boulders and mixed soils.

La ditta si riserva il diritto di modificare in qualsiasi momento caratteristiche tecniche e dimensioni.

Products

- Pipes

- Monolite 2000® Inspection Manholes

- Preformed units with rectangular section

- Drain canals and flumes for main networks

- New Jersey safety traffic barrier

- Microtunneling

- Elliptical pipes

- Circular pipes with a flat base with GLIPP joint

- Circular pipes with GLIPP joint

- Manhole pipes

- Circular pipes with a flat base with G-RING joint

- Ovoidal pipes

- Concrete and polycrete Jacking pipes

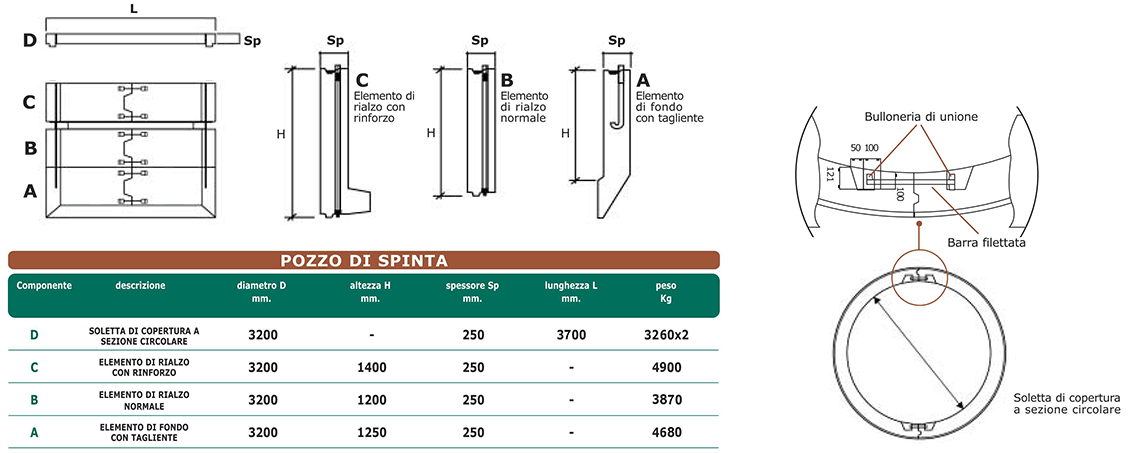

- Jacking shaft

IL.CE.V. s.r.l.

30014 Cavarzere (VE)

Partita IVA 04185330273